Laser-cutting services have emerged as a cornerstone of modern manufacturing, offering unparalleled precision, speed, and versatility in the fabrication of various materials. From intricate designs to high-volume production runs, laser cutting technology has revolutionized the way industries across the globe approach the creation of components, parts, and products. In this article, we’ll delve into the world of laser cutting services, exploring its applications, benefits, and advancements that continue to shape the landscape of manufacturing.

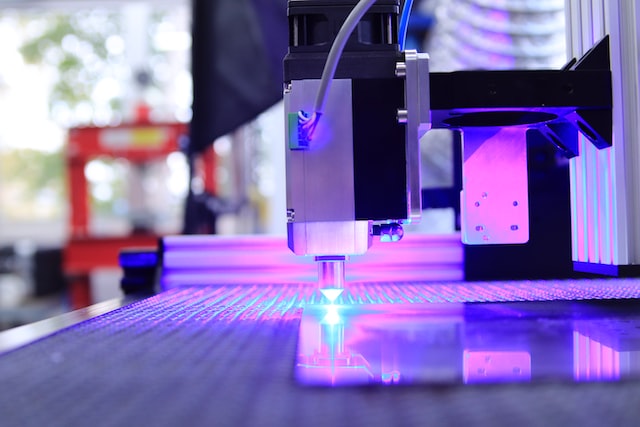

At its core, spectrum laser cutting involves the use of a high-powered laser beam to precisely cut or engrave materials with exceptional accuracy and detail. The process begins with the creation of a digital design or blueprint, which is then transferred to a computer-controlled laser-cutting machine. The laser beam is directed onto the material’s surface, where it heats and vaporizes or melts the material along the desired cutting path, resulting in clean, precise cuts with minimal waste or distortion. Laser cutting technology is capable of cutting a wide range of materials, including metals, plastics, wood, fabric, glass, and ceramics, making it a versatile solution for diverse manufacturing needs.

One of the primary advantages of laser cutting services is their unmatched precision and accuracy. Unlike traditional cutting methods, such as sawing or shearing, which can result in rough edges or irregular shapes, laser cutting technology produces clean, sharp cuts with tight tolerances, ensuring consistency and quality across each piece. This precision is especially beneficial for industries that require intricate or complex designs, such as aerospace, automotive, electronics, and medical device manufacturing, where even minor deviations can impact performance and functionality.

Furthermore, laser cutting services offer exceptional speed and efficiency, allowing for rapid prototyping, production, and customization of parts and components. Unlike manual or semi-automated cutting processes, which can be time-consuming and labour-intensive, laser cutting machines operate with remarkable speed and accuracy, significantly reducing lead times and production costs. This increased efficiency enables manufacturers to meet tight deadlines, respond quickly to market demands, and scale their operations with ease, making laser cutting an invaluable tool for streamlining manufacturing processes and improving overall productivity.

Moreover, laser cutting technology enables the creation of intricate and detailed designs that would be impossible or impractical to achieve with traditional cutting methods. From intricate patterns and decorative motifs to precise geometric shapes and complex contours, laser-cutting machines can reproduce even the most intricate designs with stunning accuracy and detail. This versatility opens up a world of creative possibilities for designers, artists, architects, and engineers, allowing them to explore new concepts, experiment with different materials, and bring their visions to life with unprecedented precision and craftsmanship.

Additionally, laser cutting services offer exceptional versatility and flexibility, accommodating a wide range of materials, thicknesses, and applications. Whether cutting thin sheets of metal for precision engineering components, engraving intricate designs onto acrylic for signage and displays, or etching personalized designs onto wood or leather for custom products, laser cutting technology can handle a diverse array of materials and projects with ease. This versatility makes laser cutting services suitable for a wide range of industries, including manufacturing, aerospace, automotive, electronics, signage, jewellery, fashion, and more, where precision, quality, and customization are paramount.